back seal test port|forum back seal testing unit : importer Ocean-5® BT01 is an ROV operated Back Seal Test Unit. The BT01 is designed to be easily mounted on Schilling Rigmaster manipulator (or other surfaces) and allows ROV to conduct pressure verification tests on . Resultado da The player from Poland is experiencing difficulties withdrawing their winnings due to ongoing verification. A few days after the complaint was submitted, the player was able to complete the verification process and receive the winnings.

{plog:ftitle_list}

Doncaster racecard & betting odds from William Hill. Free Racing Post spotlight & verdict on all horse racing.

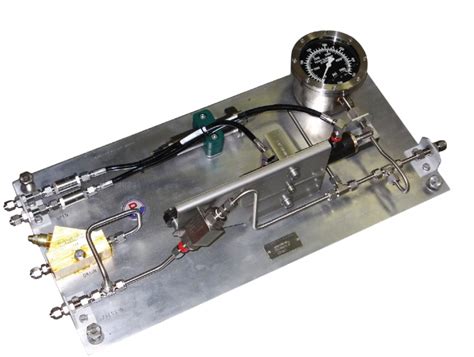

The Seadraulics Back Seal Test Panel design allows controllable and safe subsea pressure testing. Across wide range of pressures, standard units can be set for relief pressures of 50 – 6000psi. (Two versions, with Gauge options, to . Ocean-5® BT01 is an ROV operated Back Seal Test Unit. The BT01 is designed to be easily mounted on Schilling Rigmaster manipulator (or other surfaces) and allows ROV to conduct pressure verification tests on .

The BSTU provides a controllable pressure between 7 and 210bar to be applied via the pressure out connection. The pressure developed is monitored by a transducer which may be .Ocean-5® BT01 is an ROV operated Back Seal Test Unit. The BT01 is designed to be easily mounted on Schilling Rigmaster manipulator and allows ROV to conduct pressure verification .The TMT Back Seal Test Unit is a compact tool that allows the ROV to conduct pressure verification tests on subsea equipment, typically back seal test ports.The Seadraulics Pty Ltd Back Seal Test panel – designed to allow controllable safe pressure testing across a wide range of pressures. 10 – 15000psi. Test pressure supplied to the input is limited by the Pressure set at the Relief.

The TMT Back Seal Test Unit is a compact tool that allows the ROV to conduct pressure verification tests on subsea equipment, typically back seal test ports. Hydraulic fluid is supplied .

10k Test panel / Back Seal Test Unit. IHPU, DWP & Fluid Injection. Add to Enquiry List Enquire Now. Key Features. Visual subsea display gauges showing injection pressures at both ends of .

The back seal test panel is designed to allow a controllable pressure of between 10-300 bar at the output connection. The pressure supplied to the unit is controlled via a relief valve connected into the line which can be manually .The Seadraulics Pty Ltd Back Seal Test panel – designed to allow controllable safe pressure testing across a wide range of pressures. 1000 – 20000 PSI. Test pressure supplied to the input is limited by the pressure set at the relief.The Seadraulics Pty Ltd Back Seal Test panel – designed to allow controllable safe pressure testing across a wide range of pressures. 10 – 15000psi. Test pressure supplied to the input is limited by the Pressure set at the Relief.

The purpose of the reverse integrity test ring (or a back seal test ring) is to verify that assembly of the TPC Clamp Connector has been successfully performed, and that seal surfaces are good and well sealed, all without having to .Back Seal Test Panels. Return to ROV Tooling. Search products. Select All. X Products selected. Clear all. Enquire about Products . J2 Subsea 0-300 Bar WP BST View product detail. Add to enquiry Specialist Offshore Back Seal Test Panel View product detail. Add to enquiry .

Choose from our selection of test plugs, including wing nut expansion plugs, expansion plugs, and more. In stock and ready to ship. . These extra-long plugs allow you to seal off two pipes at the same time. They have two separate inflation chambers to release back pressure gradually and prevent splash back as water clears the drain line.

Do not blow air into any test port on the device. Here is Febco's procedure for drainage and freeze protect. You do need air but the connection needs to be past the preventer. On the diagram it would be a location "E" and there should be a .BX cross sections are manufactured with an extra 5mm height for the test port to clear the flanges. The extra height has minimal effect on tension, load or stress and can be calculated by all bolting specialists.

this is for the test port cap next to the alternator I don't think an o ring would seal it because the old test port cap had no o ring Sent from AutoGuide.com Free App . 2006 LLY crew cab 2500 short bed with 212,000 miles, XD misfit flat black rims with 285 70r17 BFG KOS, 5 inch MBRP dp back stright pipe exhaust ,EGR blocked, AFE stage 2 intake . Each piston assembly has two lip seals mounted in grooves on the pistons. The rearmost piston cup or lip seal holds the fluid in the master cylinder and against the back of the forward cup. . The compensation port, which is located forward of the breather port, allows fluid pressure to bleed out of the cylinder bore when the brake pedal is .

Back Seal Test Panel 20000PSI; Back Seal Test Panel 6000PSI; BOP Pump; Chemical Injection Pump – High Flow; Chemical Injection Pump – Low Flow; . 1/2” NPT Port Size; Duplex Stainless 2205 or Super Duplex Stainless 2507 . Download Spec Sheet. Type B Single Port Hot Stab quantity. Add To Quote.Installs in duct as small as 2" diameter using the 3/8" field installed test port Provides liquid tight seal - does not compromise the integrity of the duct interior coating TEST PORT NPT Fab-Tech An Exyte Group Company Drill Hole & Insert Port Insert & Seat Seal Tighten Nut & .

forum back seal testing unit

The principle applied in the leak test is based on pressurizing the annular space above and below the seal ring. If no pressure loss is experienced in this pressurization, the seal is deemed tight. The test pressure is applied to the annular space by drilling a hole through the flange into one of the annular spaces.Back Seal Test Panel 15000PSI; Back Seal Test Panel 20000PSI; Back Seal Test Panel 6000PSI; BOP Pump; Chemical Injection Pump – High Flow; Chemical Injection Pump – Low Flow; Double Block And Bleed; Duplex Piston Pump (5KSI 50HP) Fluid Injection Unit 220bar; Fluid Injection Unit 420bar; Fluid Injection Unit 520bar; Fluid Injection Unit .Back Seal Test Panel 15000PSI; Back Seal Test Panel 20000PSI; Back Seal Test Panel 6000PSI; BOP Pump; Chemical Injection Pump – High Flow; Chemical Injection Pump – Low Flow; Double Block And Bleed; Duplex Piston Pump (5KSI 50HP) Fluid Injection Unit 220bar; Fluid Injection Unit 420bar; Fluid Injection Unit 520bar; Fluid Injection Unit .and secondary seals. 4 Pressure Monitoring Pressure changes within the sealed recess are monitored from outside the flanges via the test equipment. If the seal is sufficient, the pressure will be maintained. Conversely, in the event of a seal fault, failure to hold the pressure can provide an indication of a leak path between the gasket and the

The back seal test panel is designed to allow a controllable pressure of between 10-300 bar at the output connection. The pressure supplied to the unit is controlled via a relief valve connected into the line which can be manually . The tool is designed to be secured to a flange face with a flange seal creating a test pressure annulus on the I.D. of the weld. The user then pressurizes this zone through a test fill port (with water) and vents air out of . Table B.57 and B.58 provide test port information based on working pressure. Is this working pressure of the flange, or should it be based on the highest test pressure? . Table B.57 and B.58 refer back to figure 19, which is a 9/16" AEHP port (30k rated port). You can use, 9/16" AEHP or 1/2" NPT (10k max WP, 15k max TP)for you flange.Ocean-5® BT01 is an ROV operated Back Seal Test Unit. The BT01 is designed to be easily mounted on Schilling Rigmaster manipulator and allows ROV to conduct pressure verification tests on subsea equipment, typically back seal test ports. Variable pressure of up to 15kpsi can be supplied to the unit and is constantly monitored via a subsea rated

We carry a large selection of hydraulic test port fittings at Wainbee.com. Browse our large selection of hydraulic test port couplers. Shop online for great deals! The store will not work correctly in the case when cookies are disabled. . keyboard_arrow_left Back. Fastest Seal Kits. View all . keyboard_arrow_left Back. Connector Rebuild Kits .M FOW DESN /Accessories / F119.7 Pressure Temperature Test Port 2 P/T Port The P/T port has an advanced cap design utilizing a “ground-joint union” style seal backed with an O-ring. The knurled cap permits proper finger tightening as opposed to over-tightening with a wrench. The cap strap can also be used to attach tags directly toAPI-17H Dual Port Hot Stab. Ocean-5® Dual Port Hot Stab is based proven design. VIEW DETAIL Back Seal Test Unit. Ocean-5® BT01 is an ROV operated Back Seal Test Unit. VIEW DETAIL Flying Lead Orientation Tool (FLOT) Ocean-5® Flying Lead Orientation Tool is designed for Class 1-4 Torque Tool. Products. ROV Tooling Skids;

feuchtigkeitsmessgerät beton laser

The dynamic secondary seal will accommodate the relative motion between at least one of the seal faces and the component to which it is mounted. Factors that increase seal life include seal design and material selection, process and environmental controls, and equipment optimization. Mechanical seals are used with many process fluids.120°C. Featuring a #7 Ace-Thred sample port, these tubes offer the convenience of sampling while W remanii ng connected to the researchers ’ apparatus. ITEM Pressure Vessels Featuring Ace-Threds for Threaded PTFE Plugs Front Seal Back Seal Length Approx. Tube only Complete (below thread), cm Body O.D., mm Total Capacity, mL Order Code Order . Back Seal Test Panel 15000PSI; Back Seal Test Panel 20000PSI; Back Seal Test Panel 6000PSI; BOP Pump; Chemical Injection Pump – High Flow; Chemical Injection Pump – Low Flow; Double Block And Bleed; Duplex Piston Pump (5KSI 50HP) Fluid Injection Unit 220bar; Fluid Injection Unit 420bar; Fluid Injection Unit 520bar; Fluid Injection Unit .

I did do these seals before in Jan 2017 but I think they wern't OEM MB seals and now I have leaks again. Plus, last time I DID NOT do the 'Oil Pressure Test Port' seal shown in post # 5 (the little rectangular rubber seal), and I suspect that a good amount of the oil is seeping from it. So, with MB seals on hand for: test port, base of filter .Back Seal Test Panel 15000PSI; Back Seal Test Panel 20000PSI; Back Seal Test Panel 6000PSI; BOP Pump; Chemical Injection Pump – High Flow; Chemical Injection Pump – Low Flow; Double Block And Bleed; Duplex Piston Pump (5KSI 50HP) Fluid Injection Unit 220bar; Fluid Injection Unit 420bar; Fluid Injection Unit 520bar; Fluid Injection Unit .

feuchtigkeitsmessgerät beton obi

web14 de fev. de 2024 · MP_CliReg.log: Records the client registration activity processed by the management point. Site system server: MP_Ddr.log: Records the conversion of XML.ddr records from clients, and then copies them to the site server. Site system server: MP_Framework.log: Records the activities of the core management point and client .

back seal test port|forum back seal testing unit